Concrete

July 28, 2023

60 years with vibratory equipment, machinery for the concrete industry, quality, and a strong workplace culture

Quality, responsibility, and respect: Those are some of the key values that permeate SKAKO, and history shows that this has always been the case.

On 1 July 2023, we can celebrate our 60-year anniversary at SKAKO. According to one of SKAKO’s founders and two former directors, SKAKO has been a company with strong work culture and talented, responsible employees throughout all the years. They also point out SKAKO’s products, which, to a large extent, are the same as those developed back in the 1960s; concrete mixers, concrete bucket conveyors, vibratory feeders, vibratory screens, etc. All though the products have been developed over time, the core technology of the products is still the same.

To mark the anniversary, SKAKO is hosting an open house reception on 29 June and an event for the employees in September.

It all began with vibration technology, which paved SKAKO’s way into the concrete industry

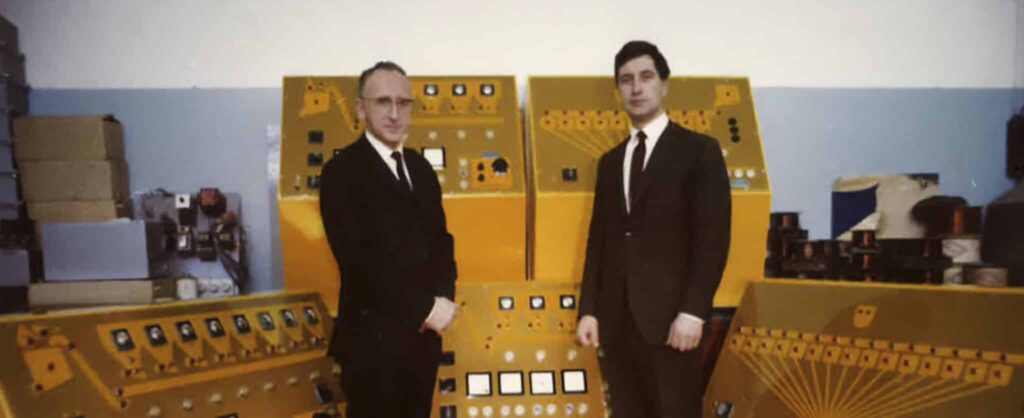

In 1963, Valdemar Skak (1913-1999) and Frits Korsgaard founded SKAKO. We have talked to Frits Korsgaard about his memories of his “extra child” as he affectionately calls SKAKO.

He particularly recalls the fruitful collaboration he shared with Valdemar Skak during the company’s first decade, which was a period of remarkable growth, increased revenue, and rapid development.

The journey that began 60 years ago started in Denmark with a new type of vibrator that was applicable in various industries, invented by Valdemar Skak.

“One day, we received an order from a concrete factory who had heard about our vibratory feeders which they believed could be useful for them. They wanted to use the vibratory feeders to proportion sand and stones for their concrete, and in this way, we entered the concrete industry,” says Frits Korsgaard.

Today, SKAKO has two divisions: Concrete and Vibration. SKAKO Concrete design and develop equipment and plants for the concrete industry, while SKAKO Vibration design vibratory equipment for the recycling, mineral, and fastener industries.

Following the order from the concrete factory, Frits Korsgaard had an innovative idea. In the 1960s, most concrete companies mixed the concrete manually. The sand and gravel for the concrete were loaded by hand with shovels, which was a heavy and time-consuming work. Therefore, SKAKO decided to develop the mixing process and launch an automated solution to control the proportioning of aggregates for the concrete – the “SKAKOMAT.” This product is still available today in a more advanced and digital version.

From this point, SKAKO started to take off:

“The SKAKOMAT solution quickly became the top-selling product in Denmark. Even today, I can still recall the names of most Danish towns because I visited almost all approx. 400 Danish concrete factories back then,” remembers Frits Korsgaard.

Emphasizing quality and customer satisfaction

Soon, Sweden, Norway, and Germany discovered the potential of SKAKO, and so the company became international. This prompted the decision to change the company’s name from Skak & Co. to SKAKO as the company wanted a name that would work in different languages. The name is a combination of the initial letters of the founders’ surnames: SKAk and KOrsgaard.

Today, SKAKO has subsidiaries in various countries, including France, Spain, the United States, Germany, and the UK, and operates in even more markets. We are especially well-known for the quality of our products, which was also a core value upheld by Valdemar Skak and Frits Korsgaard in their management of SKAKO.

“In addition to encouraging a positive work environment for our employees, technological integrity was very important to us. Our products needed to meet high technical standards. Of course, sometimes errors occur, but then it is essential to rectify them, ensuring a satisfied customer in the end. We believed in providing an exceptional service – it is better to be too service-minded than the opposite,” says Frits Korsgaard.

Frits Korsgaard recalls a particular Danish customer who was facing a significant expansion and requested quotations from multiple suppliers, including SKAKO:

“Having provided the quotation, we had a meeting with the customer, where the director of the company shared a story about a man in the United States who wanted to purchase a new car. One provider said that their gearbox outperformed the Ford gearbox, while another claimed that their steering system surpassed the Ford steering system. This pattern continued with several providers, all comparing themselves to Ford. However, in the end, the American man chose to buy a Ford; he deemed it to be the best brand because everybody compared themselves to this brand. This was also the reason why the customer had chosen SKAKO for the job, the director explained”.

Long seniority and mutual respect

To be able to continuously supply quality products, a company must be well-organized. Valdemar Skak and Frits Korsgaard knew that, but the structure of SKAKO has also been important to many of SKAKO’s managers and directors throughout the years.

Carl Christian Graversen, who worked at SKAKO from 1986 to 1991 and returned in 2003 as Finance Director, and later promoted to the director of the Vibration division, encouraged an environment where everyone felt welcome to approach him, regardless of their job description.

“I have always enjoyed working at SKAKO. The collaboration was exceptional; we stood together and worked towards a shared vision. It was not just about respecting the director; we respected each another and valued each other’s contributions. I had many wonderful colleagues at SKAKO, both in Denmark and internationally, and many of the employees stayed at SKAKO for a long time. This was advantageous in terms of keeping organizational experience and nurturing strong customer relationships, which are paramount to the success of the business,” says Carl Christian Graversen.

Carl Christian Graversen continues:

“I always prioritized having a well-structured organization as it serves as the foundation for a positive development. Unexpected challenges like Covid-19 or war may arise, but with a strong, well-structured organization, we have done everything within our control. It is all about having the right people in the right positions and having faith in their skills and expertise. And then it is important to give the employees the autonomy to act and take responsibility within their respective domains.”

That is also how SKAKO operates today, with talented employees to manage the different work areas and a top management ensuring that the pieces of the puzzle fit together with appropriate staffing in the different areas.

Carl Christian Graversen is pleased to see that many of the colleagues from his time at SKAKO are still working at SKAKO:

“Many of the driving forces are still there, and several new talented people have joined the company as well. So, it is no wonder that SKAKO has been through such a positive development the last couple of years.”

An eventful time in the German market

The 1980s and early 1990s were eventful years for SKAKO, with Mogens Thorseng playing a significant role. He joined SKAKO in 1971 as a Sales & Project Engineer, quickly ascending to the position of Sales Director and later director of the Concrete division. Reflecting on his career, it is especially SKAKO’s effort in the German market that stands out:

“We had the task of conquering the German market. Initially, it was a challenging job, but in the 1980s, when we bought 51 percent of a small competitor in West Germany, we gained a foothold in the market. It also helped that we learned more about weight proportioning, which was in high demand, and that we were able to offer this solution to the market. After the fall of the Berlin Wall, things truly took off as substantial investments were made to rebuild East Germany. This led to an immense demand for concrete – and for concrete plants, of course,” says Mogens Thorseng, who recalls getting a speed ticket in Southern Denmark because he had to rush to Hamburg for a crucial customer meeting. However, the fine was acceptable as this particular customer ended up placing many orders at SKAKO.

Mogens Thorseng continues:

“After the fall of the Berlin Wall, we hired a salesman for the East German market and established a sales and service department in his hometown Dresden. With his extensive network, this salesman opened many business opportunities for SKAKO. This affected significantly the development in the East German market that SKAKO experienced during those years.”

A strong product range and good drawings

Besides the events in the German market, Mogens Thorseng also recalls the development in other European markets and the United States:

“We managed to find the right salesmen abroad and establish offices in different markets. Being international is a strength, as it minimizes the vulnerability of the organization. When one market faces challenges, another market is usually easier to approach,” Mogens Thorseng remarks.

Besides the ability to recruit talented employees in Denmark as well as in other countries, Mogens Thorseng identifies several key factors that have enabled SKAKO to endure for 60 years. Like Frits Korsgaard and Carl Christian Graversen, he points out SKAKO’s product range which has been strengthened over time, the strong work culture, and the mutual respect among the employees. Additionally, he views SKAKO’s drawings of the customers’ plants as a key asset:

“A good drawing was a crucial selling point, and our layout designers possessed remarkable flexibility, speed, and expertise. Every drawing we produced was tailored, whereas many of our competitors made more standardized drawings. We used drawing machines to get the lines straight and the angles right. At some point, we got the idea to produce stickers with our products, such as our concrete mixers, to put on the drawings saving us a lot of time. As computers began to revolutionize the industry, our drawings became more and more digital,” says Mogens Thorseng.

Today, a good drawing is still a crucial selling point. Further, the drawings also function as invaluable documentation of the plant and as installation instructions. Today’s drawings are all digital and in 3D format.

Concrete plants for the Danish Great Belt Bridge

One of the major Danish projects that SKAKO has been part of is the construction of the Great Belt Bridge. SKAKO supplied all the plants that produced concrete for the bridge, both on land and at sea:

“We supplied numerous plants located in Nyborg, on Sprogø, etc. The plants were large-scale installations with several concrete mixers in each plant. I recall a challenge with the plants at sea, as the waves had an impact on the weighing of the aggregates for the concrete, which required some correction. However, our engineering department swiftly addressed and solved this issue,” says Mogens Thorseng.

Prepared for a greener future

Today, SKAKO stands in a good position and has been through a remarkably positive economic growth during recent years.

Some of today’s major themes are AI, sustainability, and recycling such as waste separation and sorting, water reuse and reduction of cement consumption in concrete production, and refurbishment of machines and machine components.

However, on top of the list of important themes for SKAKO you still find quality solutions for our customers and a positive work culture. These fundamental elements are essential in our effort to continue the positive development.