VIDEO

Description

Same SKAKO Concrete quality as usual – with even more features

The AMX is the result of over 90 years of mixer evolution along with satisfied customers. We only use quality components for our concrete mixers and we frequently carry out checks of our suppliers delivering the components to ensure top-notch quality for our customers.

With all the same features as our previous mixer – and a bunch of new features – the AMX is designed to optimise mixing, cleaning, discharging, energy consumption, maintenance and safety in everyday use.

New evolutionary design means cost savings and reduced CO2 emissions

The design of the AMX has been changed compared to our previous mixers and other mixers on the market. This new evolutionary mixer design will have a positive impact on your company both from a sustainability perspective as well as financially due to lower operating and maintenance costs.

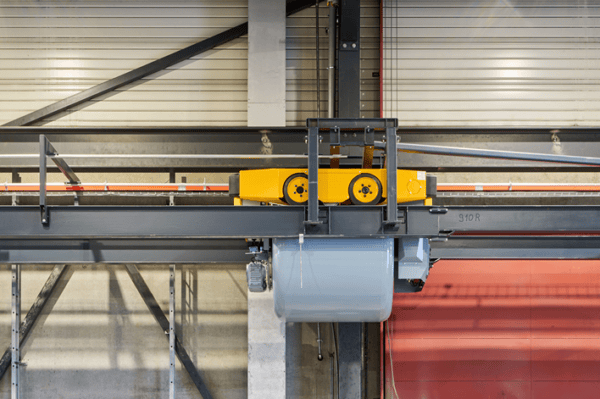

We have replaced the big gearbox you normally find on the top of a concrete mixer with a hybrid belt/chain gear system, which means that the AMX hardly uses any oil.

The hybrid drive system is based on well-known technology. It is a simple, reliable and durable technology that rarely fails – and if it does, it is easy and quick to repair.

The AMX also consumes less power than other concrete mixers due to the new design.

The design also means that the dimensions of the mixer are different from our previous mixers, which makes the AMX easier to build into existing facilities. Last, but not least, shipping of the AMX is more sustainable and the shipping costs are lower, as the mixer can be shipped as standard load rather than requiring special transportation – regardless of the mixer size.

Improves the work environment

Another advantage of the hybrid drive is that the AMX makes less noise than our previous concrete mixers. Like SKAKO Concrete’s previous mixers, the AMX also protects the mixer operator from dust emissions.

Using the AMX is extremely safe, as we provide you with the well-known key interlock system, ensuring that the hatches can never be opened while the mixer is running.

Whenever something in the mixer needs to be adjusted or the wear plates need to be replaced, this can be done from the side of the mixer. Also, the wear plates in the AMX are not as heavy as the wear plates in our previous mixers.

All this ensures fast and easy maintenance, less downtime and a better work environment.

Brochures

Specifications

Mixing abilities

With its varied shovel design and counter-current movements with different speeds of the turning shovels, the AMX creates shifting pressure and vacuum zones, eliminates dead zones, speeds up the mixing process and produces homogeneous concrete.

The interior of the mixer has no sharp edges or corners. Together with the highly effective automatic high-pressure cleaning system with multiple rotating nozzles, this prevents the concrete from getting trapped and the new batch from being mixed with old concrete.

In addition, the placement, design and size of the split discharge gate ensures a fast discharge of the concrete. The discharge gates are electrically controlled with dual actuators.

Service contract and guarantee

Together with the AMX, we offer a service contract to prolong the operating life of the mixer and an 8-year guarantee on the hybrid gear system.

The mixer can last even longer though. The operating life of a SKAKO Concrete mixer can easily be 20-30 years if taken good care of.

Technical Specifications

Products

Related products

Take the next step with us

Would you like to learn more about our solutions, or do you have any other questions? Then complete the contact form, and we will contact you shortly.