Video

Mixing abilities

With different speeds of the turning shovels and counter-current movements, the AM creates shifting pressure and vacuum zones, which eliminates dead zones. This ensures homogeneous concrete and speeds up the mixing process. The AM also has a unique two-level shovel technology with a patented shovel shape, which ensures better controlled high-intensive mixing.

Due to the advanced mixing technology, the AM provides up to 19 % less power consumption compared to similar concrete mixers on the market. The utilization of cement grains, caused by the mixing technology, increases the cement activity, providing up to 7 % savings on cement.

The interior of the mixer has a smooth surface with no sharp edges, preventing the concrete from getting trapped and the new badge from being mixed with old concrete.

Automatic cleaning system

Cleaning of the non-stick surfaces is done by the high-pressure cleaning system, working at 170 bar water pressure. The AM provides up to 50 % shorter cleaning time than similar mixers on the market, and the need for manual cleaning is virtually eliminated.

Fast discharge

The discharge gate is large, and with its outward-opening design and placement at the side of the bottom, it provides up to 23 % faster discharge compared to similar mixers on the market. This increases productivity.

Easy maintenance

Servicing of the mixer can be done through the large side hatches, using a key interlock system that keeps the workers safe.

The inside of the mixer is lined with wear plates with stud-welded fixing bolts, allowing easy and fast replacement. Adjusting the shovels is also simple and fast.

Together with the dust protection filter, all this improves the work environment for the workers operating and servicing the mixer.

Gearbox

The gearbox is integrated in the top of the mixer and can start under full load. The gear is placed in an oil sump and is self-lubricating.

Extra equipment options

The AM has a variety of options including:

- Moisture measuring probe ensuring complete consistency control

- Integrated, semi-automated, electro-hydraulic sample device

- Inspection hatch

- Remote camera for monitoring the mixing

- Infrared temperature measurement

Service contract and guarantee

Together with the AM, we offer a service contract to prolong the operating life of the mixer and an 8-year guarantee on the gearbox.

The mixer can last even longer though. The operating life of a SKAKO Concrete mixer can easily be 20-30 years if taken good care of.

Brochures

Technical Specifications

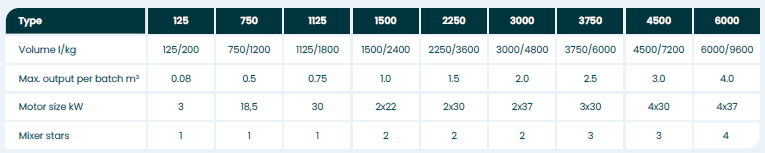

Metric

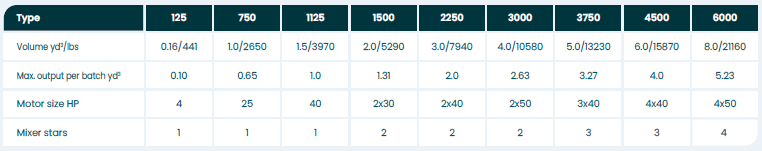

Imperial

Products

Related products

Take the next step with us

Would you like to learn more about our solutions, or do you have any other questions? Then complete the contact form, and we will contact you shortly.